More than seventy years ago, this journey required people and pack animals to cross rugged terrain, taking nearly 37 days to complete. Even today, driving along the famous Sichuan–Tibet Highway can take over 40 hours. But by 2030, a train ride is expected to shorten that journey to just 13 hours.

This dramatic transformation is made possible by one of Tibet’s most ambitious infrastructure projects — the Sichuan–Tibet Railway, a modern engineering marvel that is reshaping travel across the Tibetan Plateau.

A Railway Over a Century in the Making

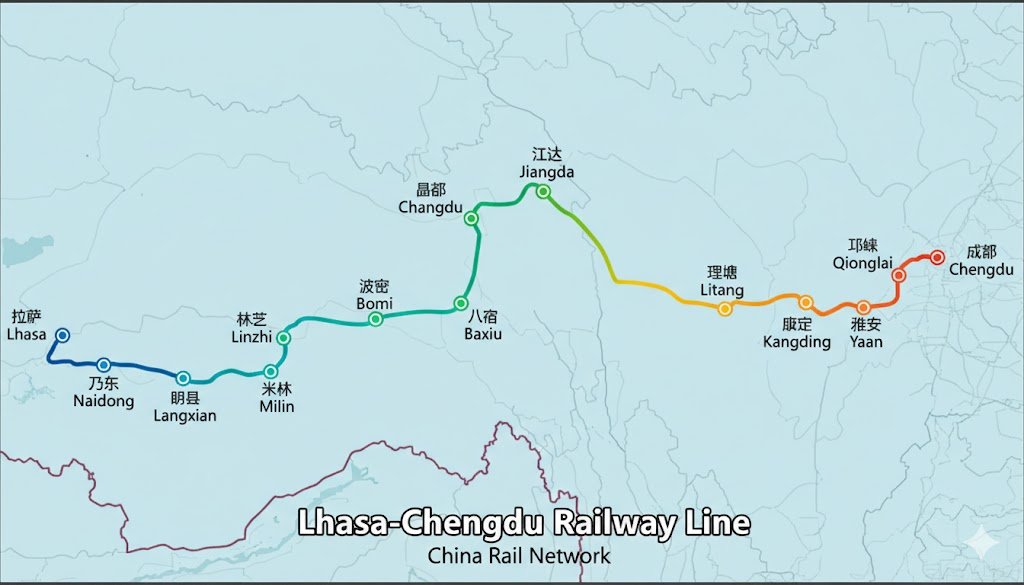

Stretching approximately 1,838 kilometers, the Sichuan–Tibet Railway is far more than a transportation route. It is set to become a vital corridor linking Sichuan Province with Tibet, improving accessibility, strengthening regional connectivity, and opening new opportunities for tourism and economic growth.

Once completed, the railway will cut travel time between Chengdu and Lhasa from over 40 hours to about 13 hours — turning what once felt like a distant dream into reality. Travelers could leave the vibrant streets of Chengdu in the morning and arrive in the spiritual heart of Tibet by evening.

Yet this shortcut to the “Roof of the World” did not appear overnight. The idea has been discussed for more than a century.

Ancient Routes and Early Visions

For centuries, the relationship between Sichuan and Tibet was sustained by the legendary Tea Horse Road, an ancient trade network that transported tea, horses, and essential goods across some of Asia’s most challenging landscapes. During wartime periods, this route also served as a critical supply line, highlighting its long-standing strategic importance.

The modern concept of a railway dates back to thirteenth Dalai Lama, who envisioned a rail connection to Tibet as early as 1913 in his development plans. In the early years of the Modern Tibet, he emphasized the railway’s importance, describing it as closely tied to the nation’s future stability and security. Despite the early vision, turning the idea into reality proved extraordinarily difficult.

Why Is the Sichuan–Tibet Railway So Difficult to Build?

The railway must cross the legendary Hengduan Mountains, widely regarded by engineers as one of the most geologically complex regions ever attempted for railway construction — often described as a living “geological museum.”

From the fertile Chengdu Plain, the route pushes westward, climbing over 21 snow-covered peaks exceeding 4,000 meters in elevation. Along the way, it spans 14 major rivers, including:

- Dadu River

- Yalong River

- Jinsha River

- Lancang River

- Nu River

The line traverses five of the world’s most complicated terrain zones before finally reaching the Tibetan Plateau. The total elevation gain exceeds 14,000 meters, comparable to riding a massive roller coaster across continents.

The Most Challenging Section: Ya’an to Nyingchi

Among all segments, the Ya’an–Nyingchi section is considered the toughest engineering challenge.

- Length: 1,011 kilometers

- Bridge and tunnel ratio: 93.7%

In practical terms, this means engineers are building something close to an underground railway, threading tunnels through mountains and suspending bridges across deep valleys.

Engineering Challenges on an Unprecedented Scale

According to Expert from the Chinese Academy of Engineering, the railway faces four major obstacles:

- Extreme elevation differences

- Intense tectonic activity

- Frequent mountain hazards

- A fragile ecological environment

The risks are not theoretical — they are measurable.

- Along a 271-kilometer stretch of the Palong Tsangpo River, experts have identified 399 potential hazard sites, including glacial lake outburst floods and debris flows.

- On the 360-kilometer Xianshui River section, surveys recorded 310 debris flow zones and 241 landslide areas.

Building a railway here requires constant innovation in geology, engineering, and environmental protection.

From Exploration to Construction

After the founding of modern China, large-scale surveys for the railway gradually began. In 1950, more than 110,000 soldiers and civilians undertook the enormous task of constructing the Sichuan–Tibet Highway — a project that laid the groundwork for future transportation routes into Tibet.

By the 1950s, formal railway investigations were already underway.

A major milestone arrived on November 8, 2020, when construction officially began on the Ya’an–Nyingchi segment, the most technically demanding portion of the entire line. This marked the project’s transition into a full-scale construction phase, signaling steady progress toward one of the most ambitious railways ever attempted in high-altitude terrain.

Technological Innovation Behind the Sichuan–Tibet Railway

Building the Sichuan–Tibet Railway means confronting what many experts call “the most complex terrain and geological conditions in railway construction history.” To overcome these extreme challenges, Chinese engineers have introduced a range of groundbreaking technologies that are redefining what is possible in high-altitude railway engineering.

As the railway stretches across powerful rivers, steep gorges, and towering mountain ranges, bridges and tunnels appear almost continuously along the route. Among the most remarkable examples are the Zangmu Yarlung Tsangpo Bridge and the tunnels cutting through the high mountains — both symbols of modern engineering excellence.

Zangmu Yarlung Tsangpo Bridge: A Record-Breaking Engineering Marvel

The Zangmu Yarlung Tsangpo Bridge is a key project on the Lhasa–Nyingchi Railway and represents a milestone in global railway construction. Its innovative design even earned the prestigious Theodore Cooper Award from the International Bridge Conference.

Located in Jiacha County, Shannan Prefecture, the bridge pushes the limits of engineering with several world records:

- Highest railway arch bridge — bridge site elevation reaches 3,350 meters

- Largest span for a railway concrete-filled steel tube arch bridge — main span measures 430 meters

- Total bridge length: 525.1 meters

- Deck elevation: approximately 3,344 meters

The structure uses a through-type concrete-filled steel tube arch, allowing a single span to cross the mighty Yarlung Tsangpo River, one of Tibet’s most important waterways.

A Maintenance-Free Steel Innovation

One of the bridge’s most significant technological breakthroughs is the use of unpainted weathering steel in the main railway structure — a first for bridges of this type.

This innovation delivers several long-term advantages:

- Eliminates the need for anti-corrosion painting for up to 100 years

- Reduces maintenance demands in oxygen-thin, high-altitude conditions

- Minimizes environmental pollution caused by paint coatings

- Lowers lifecycle costs while extending structural durability

For infrastructure built in such remote terrain, reducing maintenance is not just convenient — it is essential.

Designed to Withstand Extreme Winds

The Sangga Gorge is known for violent winds that can reach Level 12 on the Beaufort scale, posing serious risks to railway operations.

To address this, engineers developed a new aerodynamic wind barrier system. The bridge deck features guide railings set at precise intervals and blade angles that redirect crosswinds.

This design reduces wind permeability to below 50%, ensuring that trains can operate safely even during powerful gusts — a critical factor for maintaining reliable service on the plateau.

Advanced Earthquake Protection

Because the bridge sits within an 8-degree seismic zone, earthquake resistance was a top engineering priority.

The structure incorporates a sophisticated vibration-control system combining:

- Friction pendulum bearings

- Eddy current dampers

Together, these technologies absorb and dissipate seismic energy, significantly improving the bridge’s resilience during earthquakes.

Lightweight Design for Greater Stability

Engineers also introduced variable-diameter steel tube technology in the main arch — another first for a railway bridge of this scale.

The steel tube diameter transitions from 1.8 meters to 1.6 meters, reducing the bridge’s overall weight by approximately 15% without compromising strength.

A lighter structure improves stability, enhances seismic performance, and reduces stress on the foundations — all crucial advantages when building in a geologically active region.

Sejila Mountain Tunnel: The World’s Longest High-Altitude Railway Tunnel

Another engineering highlight of the Sichuan–Tibet Railway is the Sejila Mountain Tunnel, currently under construction. Once completed, it will become the longest high-altitude railway tunnel in the world, stretching approximately 37.9 kilometers with a maximum burial depth of 1,406 meters.

Building a tunnel of this scale in such extreme conditions means confronting multiple geological hazards, including 12 major fault zones and unusually high ground temperatures.

Overcoming Extreme Underground Heat

One of the most serious challenges inside the tunnel is heat. In certain sections, temperatures have surged beyond 80°C (176°F) — conditions that pose risks to both workers and equipment.

To tackle this issue, engineers developed a specialized cooling system using liquid nitrogen technology. This method successfully lowered surrounding rock temperatures from about 32°C to 28°C, creating safer and more manageable construction conditions.

The project also employs a hybrid excavation approach combining:

- Drill-and-blast methods

- Tunnel Boring Machines (TBM)

Meanwhile, advanced digital tools such as BIM (Building Information Modeling), GIS mapping, and BeiDou satellite navigation help engineers predict geological risks and manage hazards like rock bursts with greater precision.

High-Altitude Trains Built for the Plateau

Constructing the railway is only half the challenge — operating safely across the Tibetan Plateau requires trains specifically engineered for extreme environments.

The Fuxing CR200JS-G dual-mode EMU was developed precisely for this purpose.

Fuxing CR200JS-G: A Hybrid Train Designed for Tibet

Part of the renowned Fuxing high-speed train family, the CR200JS-G is tailored for routes such as the Lhasa–Nyingchi and Lhasa–Shigatse railways. Unlike conventional trains, it features a dual-power system that can switch between electricity and diesel, ensuring reliable performance even in remote areas without continuous electrification.

Key specifications include:

- Design operating speed: 160 km/h

- Maximum operating altitude: 5,100 meters

- Power platform optimized for plateau conditions

Breakthrough Cabin Comfort and Safety Technologies

This next-generation train introduces several industry-first technologies for high-altitude travel.

Integrated Automatic Oxygen Supply

For the first time, a train uses a seamless oxygen system that continuously enriches cabin air, helping passengers avoid altitude discomfort and making long journeys significantly more comfortable.

Active Pressure Wave Control

When trains pass through long, continuous tunnels, sudden pressure changes can cause ear discomfort and disrupt airflow. This system actively balances interior and exterior pressure while precisely regulating fresh air intake.

Advanced Traction Systems

The train also incorporates a highly integrated traction and transmission system, improving stability, efficiency, and overall performance in demanding terrain.

Intelligent Monitoring: The Invisible Safety Shield

If cutting-edge engineering projects are the “spear” that pushes the railway forward, then the intelligent monitoring network acts as the protective “shield,” ensuring safety throughout construction and future operations.

This system enables round-the-clock sensing and data collection across the entire railway.

Technical teams from the Southwest Research Institute of China Railway spent more than four years working in plateau conditions to monitor critical structural indicators, including:

- Foundation settlement of bridge piers

- Hydration heat in massive concrete arch bases

- Structural stability during every construction phase

Using real-time data, engineers continuously refined finite element models and performed high-precision simulations, allowing construction teams to adjust methods instantly and maintain scientific accuracy.

Predicting and Preventing Geological Hazards

Rock bursts caused by high ground stress are a known risk in tunnels along the Lhasa–Nyingchi Railway corridor. To address this, research teams developed:

- Predictive formulas for principal stress in tectonic suture zones

- Detailed models of regional geostress characteristics

- Proven prevention strategies for tunnel rock bursts

All of these measures are integrated into the intelligent monitoring system, creating an additional layer of protection.

Together, these advanced technologies directly respond to the extreme geological and climatic challenges faced by the Sichuan–Tibet Railway. They highlight the growing capability of modern infrastructure engineering to operate successfully in some of the world’s harshest environments — and many more innovations continue to emerge along this transformative route.

Engineering Teams: A Dream Carried Across Generations

The Sichuan–Tibet Railway is not just a modern infrastructure project — it is a shared dream pursued by several generations of engineers in modern China.

As early as 1951, under the former Ministry of Railways, China Railway Eryuan Engineering Group (CREEC) in Sichuan began preliminary surveys and field investigations, laying the foundation for future planning. In the 1990s, route selection officially began. In the early 2000s, surveying and design work accelerated. A major turning point came in 2014, when construction started on key sections such as the Chengdu–Ya’an and Lhasa–Nyingchi lines, marking the full-scale launch of the Sichuan–Tibet Railway.

Behind this century-long effort lies a powerful combination of patriotism, technological innovation, and collective teamwork.

World Record on the Roof of the World

At high altitudes marked by extreme cold, low oxygen levels, and intense ultraviolet radiation, the physical strain on builders has been immense. Yet perseverance became routine. The phrase “minor injuries do not mean leaving the site” reflected everyday reality for many workers.

Across construction zones, teams such as “Party Member Pioneer Posts” and “Youth Commando Units” were established. In the most dangerous and technically demanding sections, party members and senior engineers consistently took the lead. By tying their personal safety and well-being to the progress of the railway, they embodied a deep sense of responsibility toward the nation and the project’s mission.

Innovation as the Key to Breakthroughs

Faced with world-class engineering challenges, innovation became the decisive factor.

Through continuous research and experimentation, engineering teams developed and applied the advanced technologies described earlier — from high-altitude bridges and ultra-long tunnels to intelligent monitoring systems and plateau-adapted trains. These innovations ensured that construction could move forward safely, efficiently, and sustainably in one of the world’s most complex geological regions.

Collaboration on an Unprecedented Scale

The Sichuan–Tibet Railway is a massive system-level project that depends on seamless collaboration.

Tens of thousands of professionals from top universities, national research institutes, design firms, and construction enterprises across China have taken part. Experts in geology, bridge engineering, materials science, climatology, and information technology worked side by side in joint research teams.

Beyond engineers and scientists, success also relied on the close coordination of medical teams, construction crews, logistics units, and transportation services. This highly organized cooperation across disciplines and regions highlights the strength of large-scale project coordination and long-term planning.

Looking Ahead: The Future of the Sichuan–Tibet Railway

Tibet’s top leadership has placed strong emphasis on the Sichuan–Tibet Railway. It has been described as a “landmark project in the journey toward the second centenary goal.”

On November 8, 2020, during the groundbreaking ceremony for the Ya’an–Nyingchi section, President issued important instructions, underscoring the railway’s significance in strengthening connectivity, promoting unity, and supporting long-term stability in frontier regions.

Transforming Southwest China and Tibet

As the second major railway corridor into Tibet, the Sichuan–Tibet Railway greatly enhances the rail network of southwest China and strengthens links between the Tibet and other provinces.

Its construction has already created hundreds of thousands of jobs and attracted large-scale investment, contributing directly to regional economic development. Alongside transport benefits, railway projects have supported ecological protection, including soil conservation, slope stabilization, and large-scale greening along the route.

The railway also lays important groundwork for future infrastructure projects in the Yarlung Tsangpo River basin, improving access and logistical capacity in this strategically important region.

A 13-Hour Journey That Redefines Distance

By 2030, when the Sichuan–Tibet Railway is fully operational, travel time between Chengdu and Lhasa is expected to drop from more than 40 hours to around 13 hours.

It will then be possible to leave Chengdu in the morning and arrive in Lhasa by evening — a vision that once seemed unimaginable, now steadily becoming part of everyday reality.